新闻动态

中文

EN

On July 16, Walmart China made its debut at the Third China International Supply Chain Expo (CISCE), showcasing its leading solutions that leverage digital intelligence to drive supply chain innovation and sustainable development under the theme "People-Led, Tech-Powered". The showcase in Beijing’s China International Exhibition Center featured an intelligent supply chain system leveraging cutting-edge technologies including big data, artificial intelligence, and the Internet of Things (IoT) that achieves end-to-end digital transformation across all operations — from merchandising and inventory to delivery and store operations. Paul Dyck, Senior Vice President of Walmart International, outlined Walmart’s strategic approach towards sustainable development at the expo’s Green Agriculture Forum co-hosted by Food and Agriculture Organization of the United Nations and China Chamber of International Commerce.

Walmart China made its debut at the Third China International Supply Chain Expo

1.Intelligent Supply Chain Redefines Retail

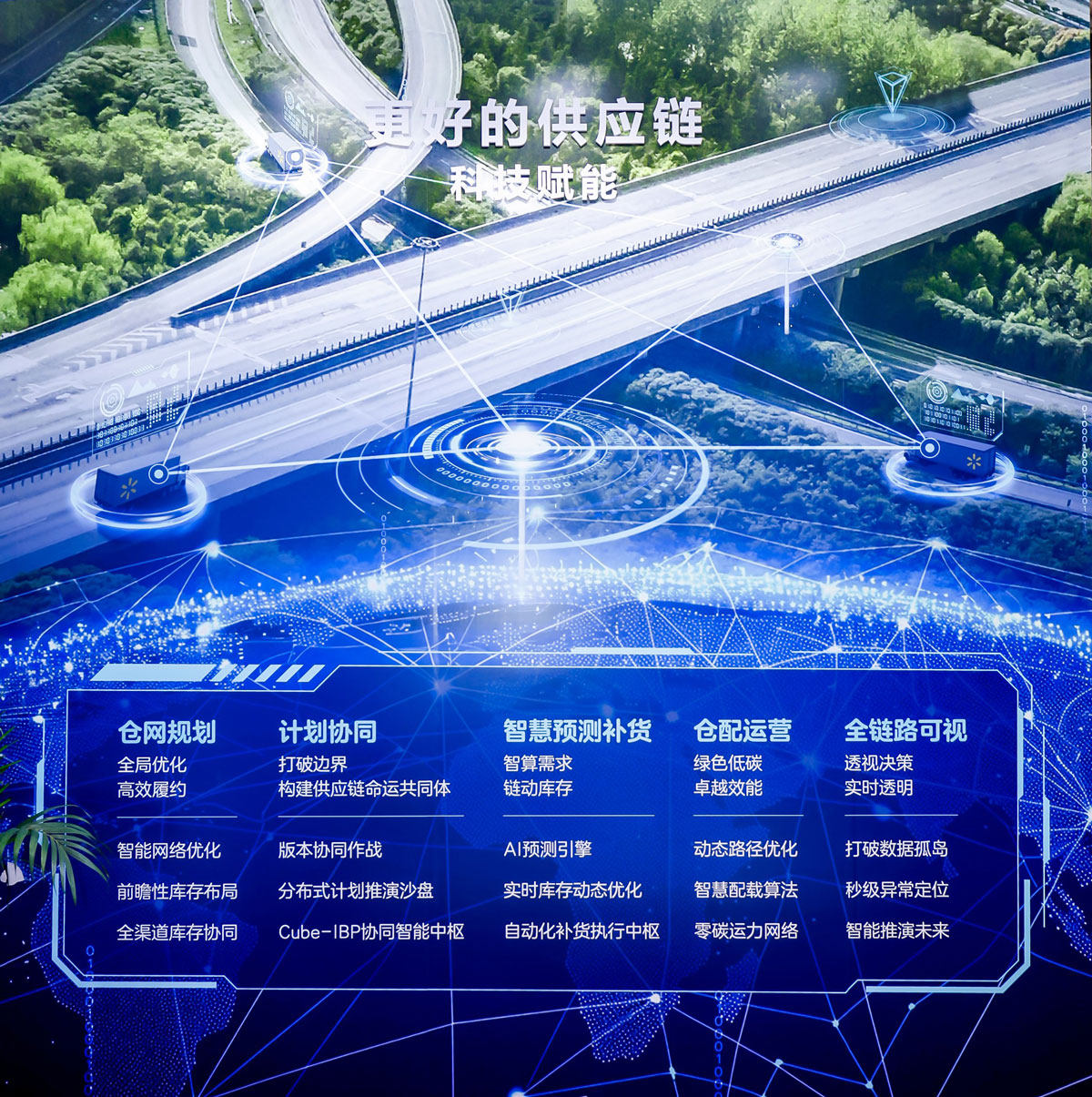

Through comprehensive adoption of smart technologies, Walmart is transforming its entire supply chain system spanning forecasting, manufacturing, warehousing, delivery and sales. Walmart advances supply chain efficiency through a continuous optimization loop — powered by data-driven decisions, algorithmic execution, and digital feedback — to deliver quality, value-driven shopping experiences.

Walmart China’s Intelligent Supply Chain

Through end-to-end digital transformation, this intelligent supply chain network achieves fully integrated intelligent management from production to end-consumer delivery. Its core lies in the efficient coordination of a centralized digital command system, enabling precise market responsiveness during both daily operations and peak seasons like holidays. This system currently covers all distribution centers, Walmart stores and Sam's Clubs, multiple regional fulfillment centers, and over 400 forward distribution centers and cloud warehouses, and efficiently processes over 30 million items daily.

Anthony Qiu, Senior Vice President of Supply Chain Integration and Technology at Walmart China, emphasized: "Digitalization transcends technological advancement — it's the core engine powering precision marketing, operational excellence, and seamless omnichannel experiences. It’s the driving force realizing integrated omnichannel operations. Through deep system integration and data-driven decision-making, we deliver superior products and shopping experiences that fulfill our mission: helping customers and members save money and live better."

● AI-Driven Forecasting and Inventory Management: Tech-Powered Precision Decision

Precision forecasting is critical for supply chain efficiency and customer satisfaction. Walmart's AI-enabled replenishment system analyzes dozens of dynamic variables, including historical sales, weather patterns, and market activities, to generate high-accuracy demand forecasting and replenishment models. Automating 90% of restocking decisions in forward distribution centers and clouds, it significantly enhances responsiveness.

The system, enhanced by large-model inventory simulation, monitors tens of thousands of SKUs across nearly a thousand inventory nodes, predicting overstock and stockout risks in real-time. For sudden high-demand items, it instantly analyzes impact and prescribes optimal inventory plans to maximize availability while minimizing waste. The intelligent decision platform leverages large language models to translate complex inventory data into plain-language insights for managers, streamlining decision-making.

● Intelligent End-to-End Implementation: Seamless Coordination from Production to Delivery

These technological innovations have demonstrated remarkable effectiveness in practical applications. For example, Sam's Club members can always purchase freshly made Swiss rolls, thanks to the precise collaboration between AI-driven production planning and bakery factories. Similarly, Walmart customers can enjoy imported beef that remains chilled from overseas factories to the store, thanks to real-time temperature control enabled by IoT across the entire supply chain.

In the fulfillment execution phase, Walmart's fulfillment middleware optimizes warehouse selection and delivery routes in real-time based on multiple critical parameters such as address matching, inventory status, and package specifications. At the fulfillment centers, the deployment of intelligent sorting robots has increased overall efficiency by approximately two times compared to traditional models.

Take Sam's Club One-Hour Delivery service as an example. Leveraging intelligent positioning systems and real-time warehouse and delivery control capabilities, even orders containing a mix of ambient, chilled, and frozen items can be processed from picking to packing within an average of just 2 minutes, with nearly all orders delivered on time within one hour. Warehouse staff can quickly and accurately locate product positions using handheld smart devices. The backend dynamically plans and allocates delivery resources based on real-time order volumes, ensuring a series of tightly integrated mechanisms that guarantee “perfect delivery” fulfillment capabilities.

● Omnichannel Matrix: Meeting Diverse Shopping Needs

Powered by robust supply chain technology, Walmart offers comprehensive shopping options. Whether customers and members choose to shop in physical stores or enjoy the fastest 30-minute delivery through the app with services like "Express Delivery," "On-Time Delivery," "Citywide Delivery," and "National Delivery," Walmart's omnichannel matrix, with various delivery times and coverage areas, meets the diverse needs of customers and members. This stems from Walmart's precise planning and layout of every supply chain link — from factory production to store shelving, from warehouse management to last-mile delivery. Through an efficient supply chain network comprising logistics distribution centers, fulfillment centers, forward distribution centers, clouds, and hundreds of stores, digitalization empowers the accuracy and efficiency of product flow.

● Quality Assurance: Safeguarding from Factory to Table

In transportation and delivery, Walmart's supply chain focuses on ensuring product quality and safety, with an emphasis on food safety. Utilizing innovative temperature control technology, Walmart has established a quality assurance system of “physical isolation + data intelligence + traceability”, precisely controlling temperature and enabling the recording and playback of full temperature data. The temperature control warning system effectively prevents temperature loss and alarms, reducing product damage rates and safeguarding freshness and safety from factory to table.

In the storefront operations, through digital innovation, the receiving system's operational process has been streamlined to five steps and completed within one minute, with inventory adjustments requiring only three steps. The intelligent display system and full-store electronic price tags work together to ensure new products can be shelved within 24 hours, significantly improving operational efficiency and allowing customers and members to enjoy fresher products promptly.

● Collaborative Win-Win: Building an Efficient Supply Chain Ecosystem

While continuously improving its own supply chain system efficiency, over the past two years, Walmart has established a digital collaborative system of “joint forecasting - production capacity coordination - platform management”, working with pilot suppliers to optimize on-time delivery rates and inventory turnover efficiency. Through an innovative “consensus plan” digital management model, it drives an increase in new product availability and significantly boosts sales growth. In building supply chain agile response capabilities, the digital prediction coordination mechanism ensures rapid response, particularly during peak demand periods like Mid-Autumn Festival and Spring Festival. These achievements lay a solid foundation for building a more resilient and efficient supply chain ecosystem.

2.Reducing Plastic and Carbon: Building a Sustainable Supply Chain Ecosystem

Paul Dyck, attending the Green Agriculture Forum, emphasized that Walmart is actively becoming a “regenerative” company, placing nature and humanity at the center of its business practices. He stated: “The communities and customers Walmart serves expect us to operate sustainably — not only to positively impact the environment and reverse ecological degradation but also to protect the core resources for future development. To this end, Walmart continues to collaborate with global suppliers, focusing on three key areas: climate action, ecological protection, and full-chain waste management, continuously creating shared value for business growth and community prosperity.”

Paul Dyck, Senior Vice President of Walmart International Delivers a Speech at the Green Agriculture Forum.

Walmart China is advancing towards the deep integration of “technology-driven carbon reduction” and “circular economy” through initiatives such as green transportation, reduced use of virgin plastics, and the development of more recycled plastic applications in logistics packaging. Among these initiatives, the large-scale deployment of new energy vehicle fleets has become a key measure for Walmart China's “technology-driven carbon reduction”.

Within nine months, Sam's Club has efficiently achieved a 45% electrification of its urban delivery fleet, with dedicated transportation management systems enabling precise management of new energy vehicles. By the end of 2025, this green fleet is expected to cover over 90% of Sam's Club's urban delivery scenarios. Additionally, optimized vehicle loading plans and the use of new energy vehicles have cumulatively reduced fuel costs by 16% over the past two years.

At the forefront of plastic pollution control, Walmart is working to build a circular economy ecosystem for storage and transportation logistics. In the effort to reduce the use of virgin plastics, reusable straps have been applied in short-distance transportation, and ultra-thin (12-micron) stretch film will be fully implemented in domestic long-distance transportation by the end of the year. Meanwhile, Walmart is collaborating with stretch film suppliers to develop a “PCR recycled plastic stretch film closed-loop recycling project”, aiming to achieve a closed-loop recycling system for used stretch film within Walmart China's operations, further deepening its plastic reduction efforts.

These green initiatives are extending throughout the supply chain, from upstream to downstream. In addition to piloting and promoting within its own system, Walmart plans to incorporate sustainable development principles into its evaluation system for storage and transportation logistics suppliers, encouraging more like-minded partners to build a green supply chain together and create "shared value" through sustainable growth.

沃尔玛

沃尔玛 山姆APP

山姆APP